In practice, however, we find we cannot lower the fiber into this optimal position because the wire bond on the bond pad is around 100 μm high. We tried raising the fiber above the wire bond, but we obtained the greatest coupling efficiency with the fiber placed flat on the surface of the LED as close to the center as we can get it. The result is shown below.

Figure: Offset Fiber. This 410-μm diameter fiber is roughly 120 μm from the center of the EZ500.

With the fiber 120 μm from the center, our incidence calculation suggests we will get 52% of the LED light incident upon the base of the fiber. With NA = 0.86, we expect 74% of the light incident upon the base of the fiber to emerge at the other end, for an expected total capture efficiency of 38%.

We run 30 mA of current through the LED. The power emitted by the far end of the fiber is 9.8 mW (photocurrent 1.77 mA and sensitivity 0.18 mA/mW). We remove the fiber and measure 25.2 mW total power output (photocurrent 4.53 mA). Our coupling efficiency is 39%. We re-position the fiber several times. We obtain 38% or 38% coupling efficiency each time.

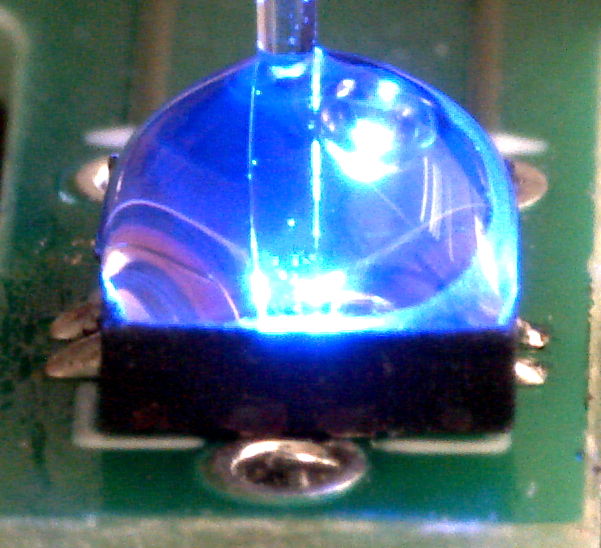

With the fiber in place, we inject E-30CL clear optical epoxy (RI = 1.5) into the LED package. The epoxy flows around the fiber and LED. The result is shown below, with a few milliamps of current in the LED.

Figure: Offset Fiber with Clear Glue.

As soon as the glue has surrounded the LED, the power at the fiber tip drops from 9.8 mW to 5.3 mW (photocurrent 0.95 mA). We raise up the base of the fiber and remove it from the glue blob and measure the total LED output to be 25.7 mW (photocurrent 4.62 mA). We replace the fiber and place it in its previous position. Once again we obtain 5.3 mW at the fiber tip. Our coupling efficiency has dropped from 39% to 21% with the application of glue.

Right now we have no explanation for this dramatic drop in coupling efficiency with the application of glue. So far as we understand, the a thin layer of transparent material between the fiber and LED will not stop light entering the fiber. Nor will glue on the outside of the fiber reduce its numerical aperture below 0.86. Nevertheless, the effect is real and repeatable. We have observed it many times, today being merely the most detailed observation of the effect to date.

No comments:

Post a Comment